Drying impregnation plant for motors/transformers

Tabo is specialized in complete plants for drying motors and trasformers; these plants let us work in a clean environment with no smells and no pollution.

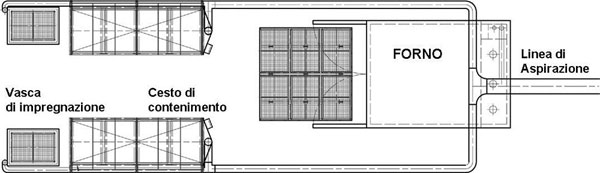

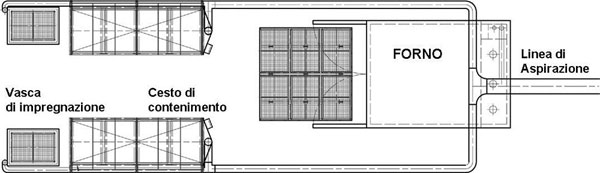

This plant consist of:

- Impregnation tanks for motors/trasformers

- Closed drip-off tanks for the drip-off and pre-drying phases

- 1 gas drying oven for motors/trasformers equipped with trolley,oven rack and/or baskets.

- 1 intake plant connected to the different installations such as gas, light etc..(not included)

From an environmetal and a technological point of view, this plant is the best product on the market because all the impregnation phases take place in an environment with no pression and all the gas/fumes are extracted from the different openings of the centralized extraction system allowing to work in a safe, non-polluted environment.

In particular, the plant consist of:

-

Impregnation tanks for Motors/Trasformers

Impregnation tanks are used to paint, through immersion windings of motors/transformers. Pieces are placed into customized baskets designed according weight and dimensions of the motors/transformers.These tanks could contain a fixed quantity of paint in a lower chamber, then, thanks to compressed air, paint comes up on the upper chamber in order to carry out the impregnation process.

-

Closed drip-off tank for drip-off and pre-drying of motors/trasformers.

This is a particular tank with a closed covering which contains the baskets coming out from the tanks, so that it is possible to carry out the drip-off and the pre-drying phases on the trasformers/motors, thanks to cold air.

These tanks are made of robust painted plate with a closed, sloping bottom base which allows to concentrate and eliminate the residual paint.

The structure is closed by means of a plate-made lateral covering and an upper cover that can be opened thanks to 2 pneumatic cylinders.

On the lateral part of the drip-off tank, there are the openings for the intake of air. These parts are equipped with a manual adjustable shutter. On the upper part, there is the pipe for the unloading of the air; even the pipe is equipped with a manual adjustable shutter.

-

Gas oven T.F.G. Model

All the information are available here DRYING OVENS.

-

Centralized intake system.

This plant is composed by different intake windows placed in each point where there are fumes (tank, oven, burner etc..). Windows are on the centralized line equipped with an adjustable shutter and centrifgal fan. The plant can also include:

This plant is composed by different intake windows placed in each point where there are fumes (tank, oven, burner etc..). Windows are on the centralized line equipped with an adjustable shutter and centrifgal fan. The plant can also include:

- Steel baskets containing the motors/trasformers

- Robust steel-made trolley to load the oven

-

Adopted technologies in order to avoid environmental pollution

Normally, it should be right to carry out 1 or 2 daily cycles; the cycle should take as follow:

- Impregnation of motors/trasformers into the tanks for 4/5 minutes.

- Placement of baskets into the drip-off tank for 4/5 hours. This is necessary to eliminate and collect the paint and carry out the first pre-drying phase thanks to the cooling system.

- Placement of the baskets into the oven following an adjustable cycle time according to the fixed temperature and the weight of the material. The expected time for this operation is 4/5 hours.

- Unloading of the dryed material from the oven.

-

Certification.

All plants are customized according the Customer needs and are supplied fully assembled and tested. They are in compliance with the European regulations in force.

This plant is composed by different intake windows placed in each point where there are fumes (tank, oven, burner etc..). Windows are on the centralized line equipped with an adjustable shutter and centrifgal fan. The plant can also include:

This plant is composed by different intake windows placed in each point where there are fumes (tank, oven, burner etc..). Windows are on the centralized line equipped with an adjustable shutter and centrifgal fan. The plant can also include: